About Us

ABOUT US

POPTAR is a leading company in the design and production of industrial keyboards, screen-printed panels, and adhesive plates in a facility of over two thousand square meters in the province of Modena.

POPTAR boasts prestigious clients operating in all industrial sectors, from automotive to electromechanics, medical to industrial automation, vending to military, packaging to agriculture, and many others.

Our product range includes:

– Dome Keyboards

– Bubble Thermoformed Keyboards

– Membrane Keyboards

– IBM-Compatible Keyboards

– Vandal-Proof Keyboards

– Capacitive Keyboards

– Rigid Circuit Keyboards in fiberglass

– Panels and Touch Screens

– Adhesives, and Plates

Company Video

HISTORY

Founded in 1969, POPTAR is a benchmark in the membrane keyboard industry, with a solid reputation for the reliability and quality of its products.

By adopting a set of established values, highly reliable processes, and solutions designed to meet the most diverse needs, the company has built an integrated system focused on complete customer satisfaction.

This distinctive approach, rooted in a strong commitment to excellence and continuous innovation, has made POPTAR a benchmark partner for those seeking uncompromising quality and flexibility in a constantly evolving market.

DESIGN OFFICE

In the design and production of each product, the company follows its customers from graphic design to the development of the electronic and mechanical components.

POPTAR’s technical office works daily to develop new concepts, improve existing projects, and create prototypes for the future.

Thanks to its ability to continuously design and improve, it has established partnerships over the years with key companies in numerous industries, reducing the time to market for our final clients, with the highest levels of quality, precision, and specificity.

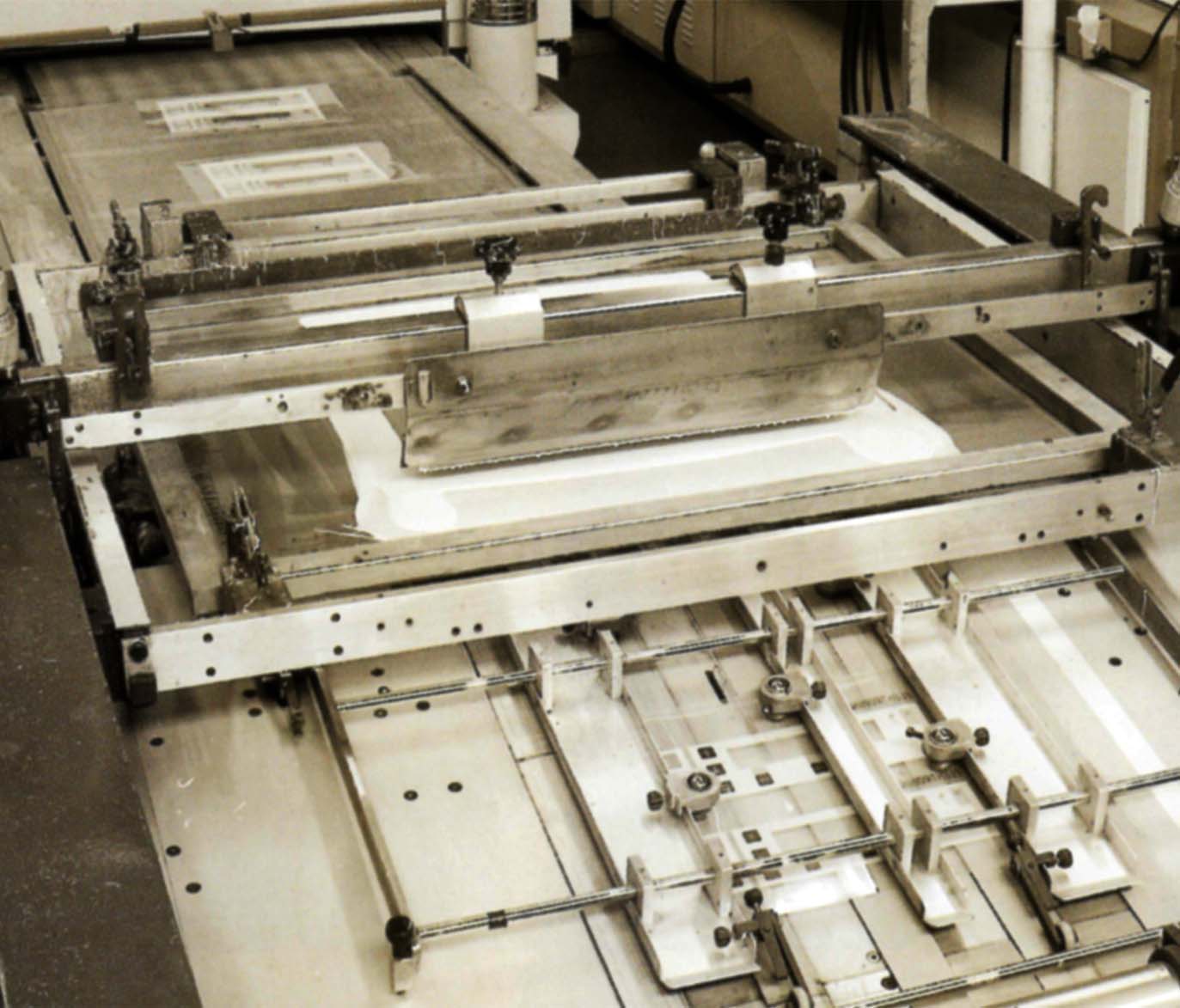

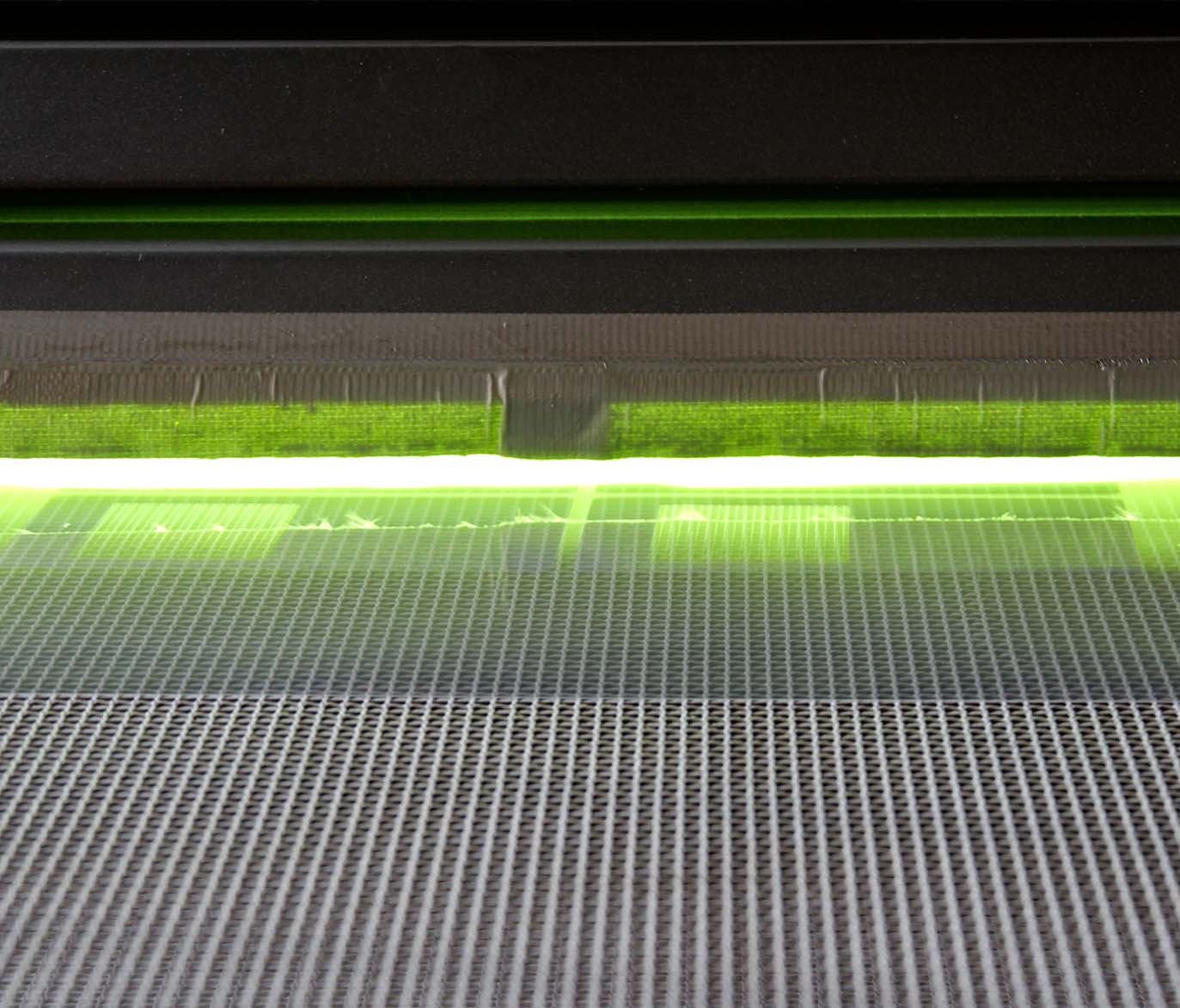

PRINTING DEPARTMENT

The printing department, equipped with traditional screen-printing machines and modern digital printers, produces front panels and electronic circuits with maximum operational and production flexibility, from small quantities to large orders, with the possibility of integrating SMD components.

GARAGE

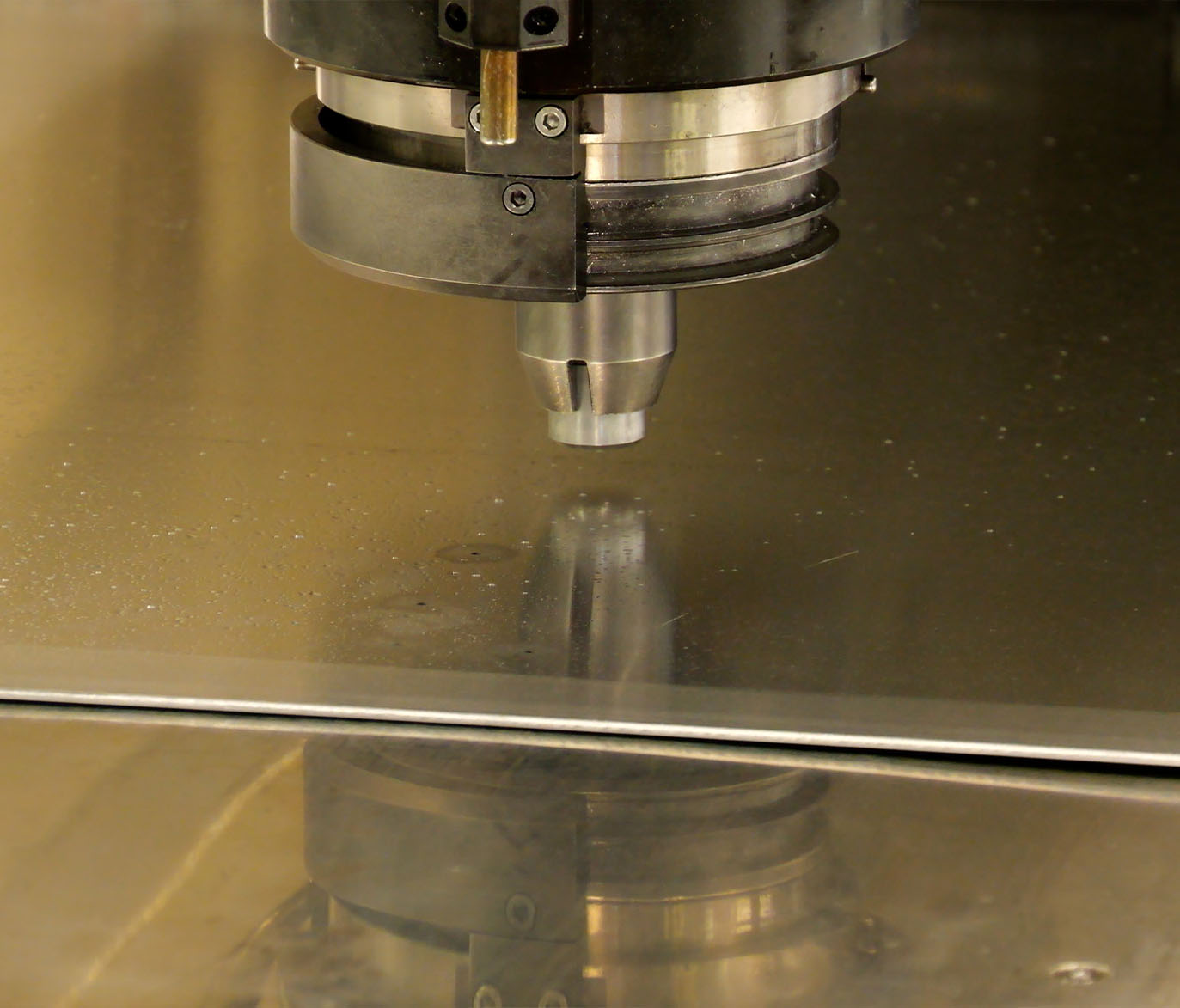

The cutting and material control phases are carried out in our departments using die-cutting and laser cutting machines which ensure efficiency and high production capacity.

The mechanical workshop, equipped with CNC punching machines, milling machines, laser cutting centers, die cutters, presses, and more, carries out the entire cycle of processing and finishing aluminum supports, ensuring optimal levels of reliability, strength, and durability.

ASSEMBLY

A modern laboratory and highly specialized human resources are at the service of the process instrumentation, thus ensuring calibrations and working parameters compliant with current regulations.

In assembly, high manual skill, experience, and attention to every phase are crucial to achieving a top-quality finished product.

To guarantee the solid reliability of POPTAR keyboards, the final testing process is performed on each individual piece. Finally, the shipping department coordinates order movements and handles the dispatch of products, with careful attention to the packaging of finished batches.